Tagging Alignment with Offline Devices

Applications for Met...Description

Conventionally, incorrect marking positions occur due to incorrect placement and misalignment of the jig resulting from manual work. To perform position marking, the entire MD-X Series requires the user to simply place the target within the area without needing to position the target or adjust the jig.

Actions

Share

Related Products

Measurements on Lathe Components

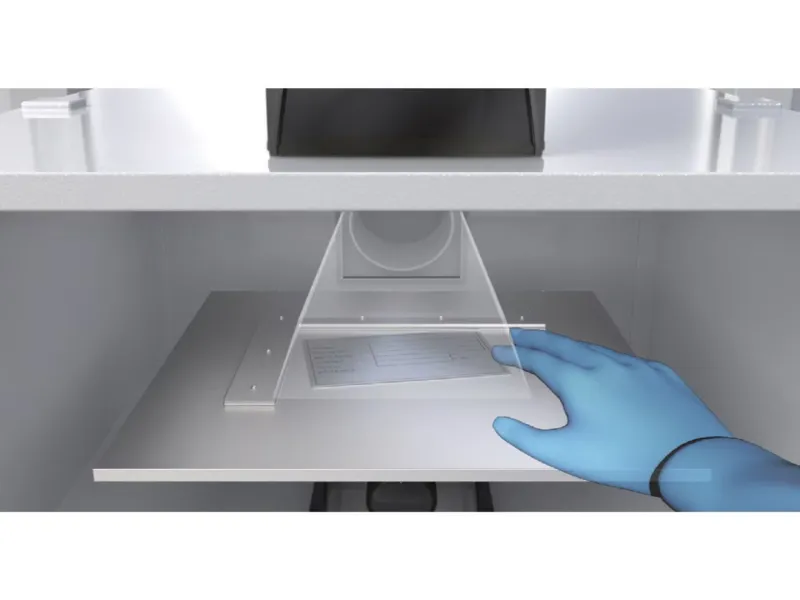

<p>The measurement system to be used is selected based on several aspects such as outer diameter, length, groove diameter and position, corner radius, and measurement location. The IM series can meet all of these criteria with one unit. This advantage has an impact on increasing sampling measurements and also improving quality thanks to predictive management.<br><img src="https://www.keyence.co.id/img/application/90849.jpg"></p>

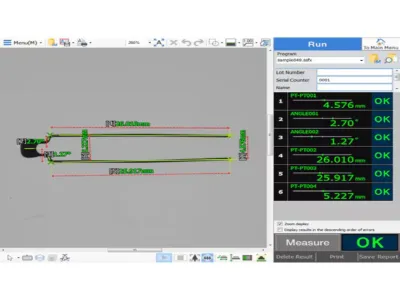

Measuring the Curvature of Electronic Component Cables

<p>The pitch and position of the cable ends are measured. With the Image Dimension Measurement System, non-contact measurements can be carried out without deformation. Simply press the [MEASURE] button to run the measurement and display the results, as shown below.<br>1. The center line of the box is detected.<br>2. The center point of the cable end is detected.<br>3. The pitch of the cable ends and the distance from the center line of the box are measured.</p>

Detection of Peeling and Scratches on Seal Edges

<p>The edges of the seal peel easily so the High Speed 2D Laser Profiler was used to check for this problem. In addition, because the location where stripping begins is unknown, the bearing must be rotated to inspect its entire circumference. Due to the miniaturization of bearings and increased production quantities of bearings, demand has arisen for short inspection times and better inspection capabilities. This High Speed 2D Laser Profiler boasts the world's highest speed at 64,000 profiles so processing can be done quickly. Additionally, because the High Speed 2D Laser Profiler has 16 outputs, a variety of inspections can be performed—such as measuring the overall height and shape of the seal and the runout of the inner and outer wheel surfaces—along with checking for edge peeling.</p>