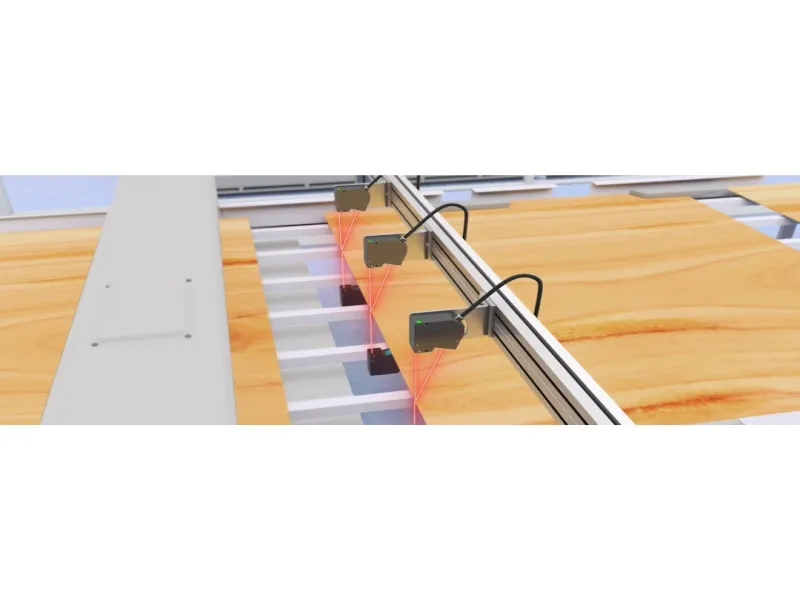

Plywood Thickness Measurements

Applications for Pla...Description

Plywood boards are made by gluing multiple veneers together, which can cause variations in thickness over width. Laser displacement sensors can be installed across the board to continuously monitor thickness variations. Thickness inspection during the manufacturing process will provide a higher yield rate, as well as quality.

Actions

Share

Related Products

Measurements on Extrusion Molded Components

<p>Capable of measuring with radiated illumination and ring illumination, the Image DImension Measurement System supports all necessary measurements with a single unit. The ability to measure instantly and significantly reduces inspection time and increases quality reliability.</p><p><img src="https://www.keyence.co.id/img/application/92802.jpg"></p>

Measurements on Injection Molding Components

<p>Capable of measuring with radiated illumination and ring illumination, the Image Dimension Measurement System supports all necessary measurements with a single unit. The ability to measure instantly and significantly reduces inspection time and increases quality reliability.</p><p><img src="https://www.keyence.co.id/img/application/90845.jpg"></p>

Appearance Inspection of Plastic Lids

<p>This is an appearance inspection of plastic caps transported on a conveyor. When performing appearance inspections for impurities, inspections for contamination may be unreliable, depending on the pattern in the product and the background color. By using blue lighting, it is possible to accurately inspect only targeted defects.</p><p style="text-align: center;"><strong>Image of defects</strong></p><p><img src="https://www.keyence.co.id/img/application/91100.jpg"></p><p style="text-align: center;"><strong>Image of defects (after color extraction)</strong></p><p><img src="https://www.keyence.co.id/img/application/91101.jpg"></p>