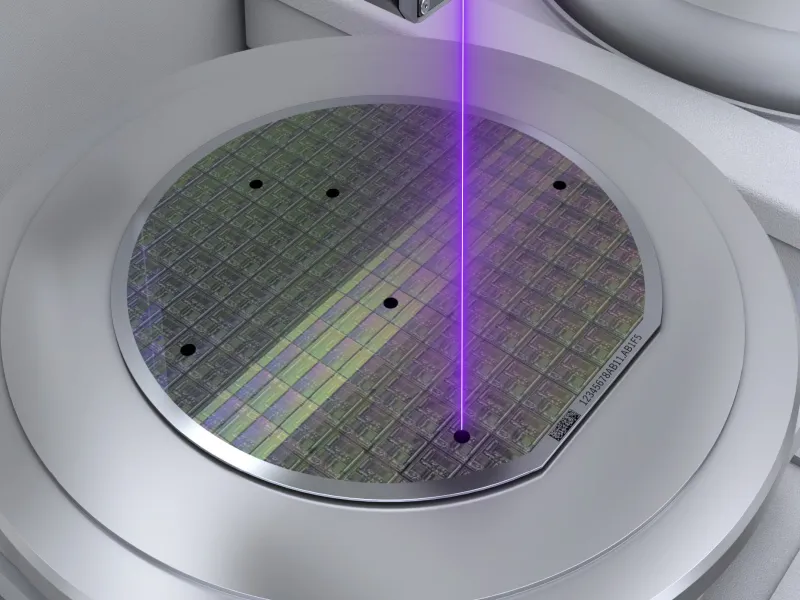

Wafer Defect Marking

Applications for Sem...Description

Conventional systems (such as ink) require that each defective chip be moved out of the stack and marked individually. The laser marker can perform touchless marking on multiple chips within its working area thereby helping to reduce the time spent on marking.

Actions

Share

Related Products

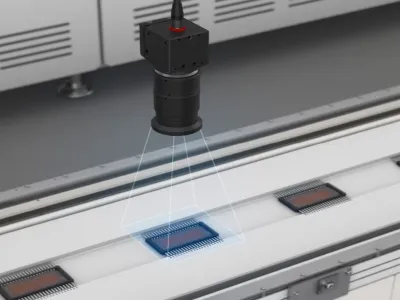

Power Semiconductor Wire Inspection

<p>The use of high-resolution cameras ensures greater clarity when examining cable details.</p>

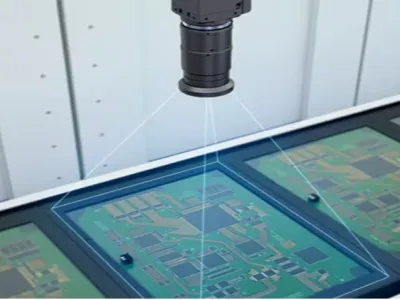

OCR with Electronic PCB

<p>While marking inspections with conventional systems means capturing separate images, processing time can be increased by capturing the entire field of view at once with a high pixel camera.</p><p><img src="https://www.keyence.co.id/img/application/90634.jpg"></p>

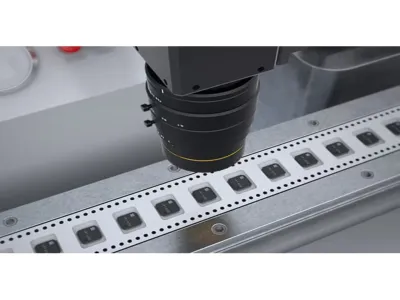

Product Type Differentiation or 2D Identification of IC Packages

<p>Reads 2D characters/codes marked with a laser on the surface of the IC chip. A single machine vision can recognize both characters, such as part numbers and 2D codes simultaneously.</p><p style="text-align: center;"><strong>OK</strong></p><p><img src="https://www.keyence.co.id/img/application/90600.jpg"></p><p style="text-align: center;"><strong>NG</strong></p><p><img src="https://www.keyence.co.id/img/application/90601.jpg"></p>