Checking the Code on the Label from the Label Printer to Improve the Quality of the Items Sent

Applications for Foo...Description

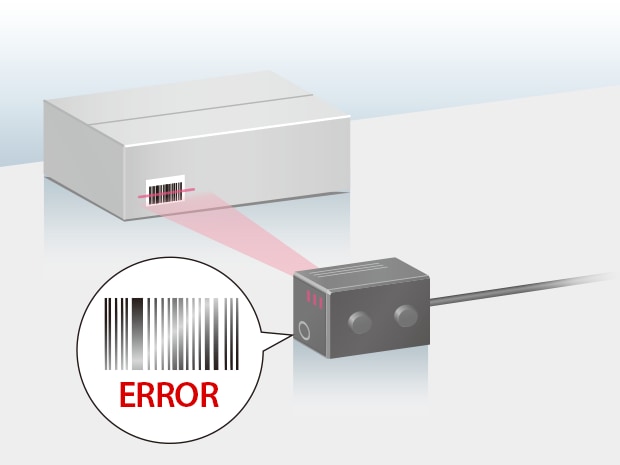

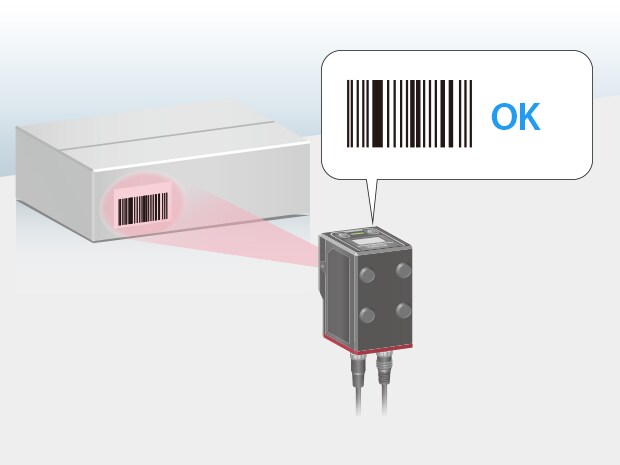

Wear on label printer components and reduced transport speed cause print damage and increase reading errors. Use the 1D/2D Code Reader conformance level function to check labels for each process and stop reading errors before they occur.

Conventional Products

Tendency for reading errors to occur

1D/2D Unitek Code Reader

See the reading margin in numbers!

Actions

Share

Related Products

Reduce Costs and Labor by Reading Multiple Products Without Changing Settings

<p>Reading products with codes printed in different places usually requires two readers. Widefield 1D/2D Code Readers can read code printed in different locations, eliminating the need for a second reader.</p><p style="text-align: center;"><strong>Conventional Products</strong></p><p><img src="https://www.keyence.co.id/img/application/95069.png"></p><p>Requires 2 units facing different directions</p><p style="text-align: center;"><strong>1D/2D Code Reader Unitek</strong></p><p><img src="https://www.keyence.co.id/img/application/95070.png"></p><p>1 unit does it all!</p>

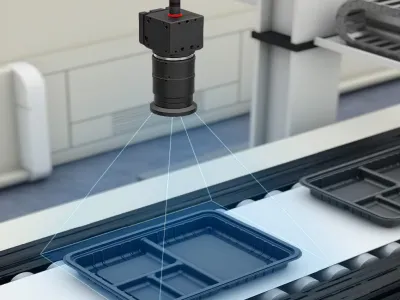

Inspection of Small Holes in Containers

<p>Inspecting small holes and stains on food containers can be done more accurately.</p><p><img src="https://www.keyence.co.id/img/application/90689.jpg"></p>

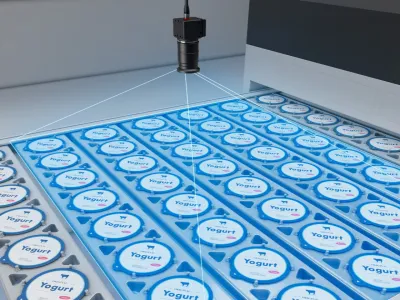

Food Container Lid Printing Alignment

<p>Compared to conventional systems that require multiple cameras for inspection, a 64 megapixel camera can capture the entire field of view at once.</p>